Cereal line for Cereals - 20478

Specifications

| Manufacturer | Sollich |

| Model | 820 / 1050 conbar |

| Year | 2017 |

| Condition | Used |

| Stock Number | 20478 |

| power | from 0 to 0 |

| output | 1 to |

Description

year of construction 2017/18 output per hour: 1 ton with large formats, 550 kg/h with small formats product: Peanut bar, puffed rice bar or cereal bar product dimensions: 109 / 100 mm length, 34 mm width, 6-10 mm height weight: 17-20 grams List of machines: 1) Syrup cooker Chocotech 2) Peanut Sieve Galaxy Sivtek 3) Elevator Fabcon 4) Screw conveyor, screw heating Sollich, with 1 continuous peanut Heating system, including mixing, with thermal oil heating of the continuous mixer, with weighing and peanut heater 5) Cardamom feed/feed Sollich, dosing type K-MV-KS 60 6) Peanut feed / Sollich feed 7) Continuous mixer Sollich type SMB 315 8) Task Sollich, with volumetric quantity measurement type TD 2, to mix in the sugar binder. 9) Carpet former, upper and lower roller with temperature control Sollich type WEB 800, carpet width 758 mm, frequency controlled, with heated feed, 3.5 m infeed table 820 mm wide, with stainless steel cooling plates, incl. photopneumatic belt control, with 1 separate control cabinet at the inlet with Sollich operation via PLC to Carpet thickness can be regulated on the WEB 800, the cooling channel temperature and the belt speed can

be regulated, including 1 WKH water circulation system for the two rollers of the WEB 800 and the feed hopper 10) Calibration roller with temperature control Sollich type SAW 800, incl. 1 cooling and heating unit 11) Cooling tunnel 1, with chiller system Sollich type KK 820, 12 m contact convection channel, including belt E8/2, with Air cooling module L 20 GL (water supply via WKH) including photo-pneumatic belt control, 1 longitudinal cutter type ABN 820 with 336 mm diameter, frequency controlled, pneumatic belt control, 1 m outfeed table 820 mm incl. Belt scraper knife, including 1 heating and cooling unit for the bottom of the infeed table, cooling table KK 820,

spreading belt, Infeed table with guillotine 12) Spreader Sollich type SL 800, with 23 rotating knives for 22 product rows, including cross conveyor to

to separate sections 13) Spreader belt type SSC 800/1050, with 22 spreader belts and 2 m acceleration belt. 14) Cutting machine Sollich type SGU 800 S, frequency-controlled drive of the knife, photo-pneumatic belt control,

Servo drive with separate control cabinet Sollich PLC for controlling the speed of the plastic belt and the Slitting device, spreading device, infeed belt of the cutter, the UPM of the plastic roller and the Product section length 15) Cooling tunnel 2 Sollich Thermo-Flow Plus type LSK 1050, with 1 m infeed table 1050, 321.12 m cooling tunnel LSK

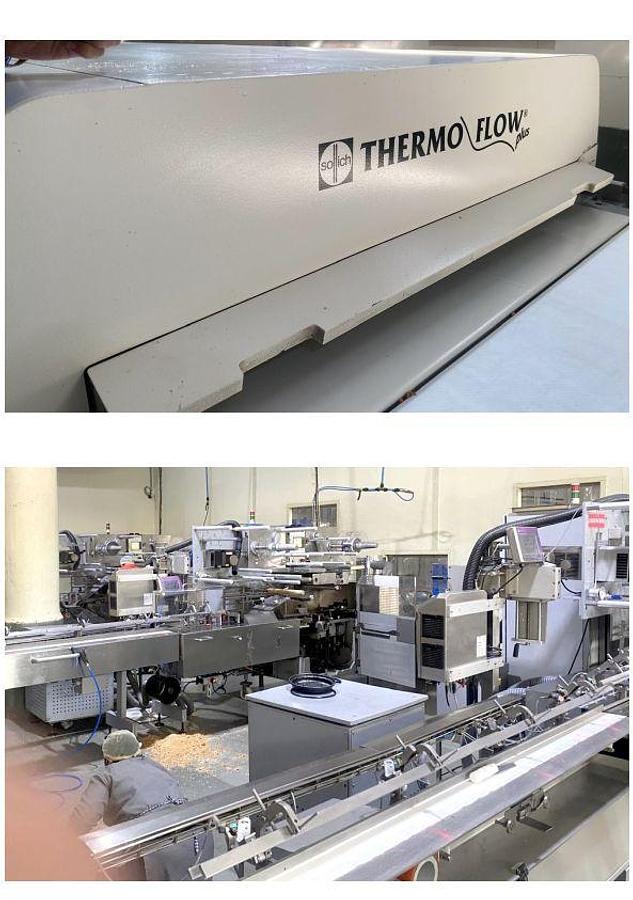

1050, including belt E8/2, with air cooling unit module L 50 GL, including photopneumatic belt control, including 1 belt

drive type ABN 1050 16) 90° curved belt Transver AG 17) ADS Station 1, 2 & 3 Theegarten Pactec 18) Metal detector 1, 2 & 3 Loma systems 19) Flowpack Machine 1, 2 & 3 ACG 20) Laser Printers 1, 2 & 3 Markem-Imaje 21) Empty packaging control Beacon engineers 22) Manual container filling station 23) Belt for filled containers Beacon engineers 24) Container Printer Markem-imaje 25) Container wrapping and shrinking Jet pack machines pvt. Ltd. 26) Manual carton filling station 27) Belt for filled boxes Beacon engineers 28) Checkweigher Ishida India pvt. Ltd. 29) Cardboard Barcode Printer Markem imaje 30) Stelda carton sealer 31) Belt for delivering filled boxes Beacon engineers The line is undismantled

Ex location